External combustion engines

An external combustion engine is a heat engine where an (internal) working fluid is compressed and heated by combustion of an external fuel through the engine wall or a heat exchanger. The fluid then, by expanding and acting on the mechanism of the engine (piston or turbine), produces a shaft power. Steam engines and Stirling engines are most known external combustion engines.

The strength of external combustion engines vis-à-vis internal combustion engines is compatibility with a wide variety of renewable energy and fuel sources. They may use a supply of heat from any sources such as biomass and biomass derived products, municipal waste, nuclear, solar, geothermal, or exothermic reactions not involving combustion. In the later case they are not then strictly classed as external combustion engines, but as external heat engines. Other important advantages of external combustion engines are low emissions, due to continuous external combustion, and low noise, due to elimination of exhaust of high-pressure combustion products.

Promising external combustion engine concepts are Stirling engines that convert thermal energy into mechanical energy of reciprocating piston(s). The pistons are moved due to a cyclic change of gas phase working fluid pressure under the influence of its temperature and volume change. High theoretical thermal efficiency (Carnot efficiency), long maintenance interval, fewer moving parts are additional advantages of Stirling engines.

In practice the Stirling thermodynamic cycle deviates from the theoretical cycle due to frictional losses, working fluid leakage, dead volumes etc. Technical problems, in particular balancing of pistons (or piston and displacer) reciprocating with a phase lag and sealing of the hot piston, currently prevent the wide application of Stirling engines.

Significant improvements of Stirling engines are expected by using engines in which the displacer is rigidly connected to the power piston. In these engines the piston-displacer assembly is moved due to the cycling pressure change of the working fluid under the influence of change of its temperature and amount inside the engine chamber. This engine concept has a number of advantages compared to state-of-the-art external (Stirling) and especially internal combustion engines. The engine has only one moving parts and no gas springs, piston rings or any other rubbing components requiring lubrication. It solves the problems of high-temperature sealing and balancing of the pistons and reduces heat losses. Moreover, both strokes of the piston are working ones in contrary to any other types of piston engines.

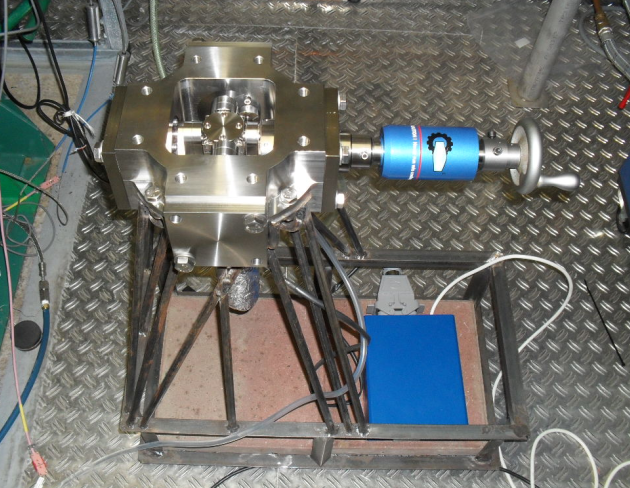

ECT has initiated the development of a radically new external combustion single-piston engine, and built a thermodynamic model of the engine (new thermal cycle), a detailed mathematical model of the engine and a numerical programme for engine performance simulation. It also prepared construction drawings for the engine that is currently being built.

ECT has initiated the development of a radically new external combustion single-piston engine (see picture below). A thermodynamic and detailed mathematical models of the engine (new thermal cycle) and a numerical program for engine performance simulation were elaborated. Using the theoretical results the engine was designed and construction drawings were prepared. After manufacturing of the engine components the engine was assembled. First engine tests have been started.